| |

|

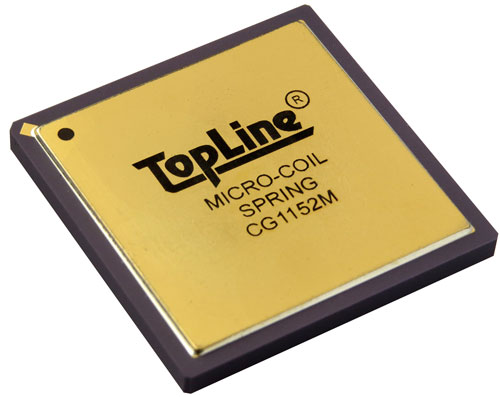

Micro-Coil Springs

MSC Series

Interconnect for CCGA |

|

| |

|

|

Pad

Pitch |

Spring

Diameter

O.D. |

Spring Length

Free Load |

Wire

Diameter |

Spring

Constant |

PCB Land Pad

Diameter Minimum |

Paste

Stencil

Thickness

Note 1. |

Part Number |

DWG

Number |

Plating |

| 1.0mm |

Ø0.40mm

0.016" |

1.0mm

0.040" |

Ø63.5µm

0.0025" |

0.4627 N/mm

2.6423 lbs/Inch |

Ø0.508mm

0.020" |

125µm

5 Mil |

MCS172P16x40 |

171640 |

Sn60Pb40

Tin-Lead

100 µ-inch |

| 1.0mm |

Ø0.40mm

0.016" |

1.0mm

0.040" |

Ø63.5µm

0.0025" |

0.4627 N/mm

2.6423 lbs/Inch |

Ø0.508mm

0.020" |

125µm

5 Mil |

MCS172G16x40 |

191640 |

NiAu

Gold 10 µ-inch

Nickel 30~60µ-inch |

| 1.0mm |

Ø0.51mm

0.020" |

1.27mm

0.050" |

Ø86µm

0.0034" |

0.6268 N/mm

3.5792 lbs/Inch |

Ø0.635mm

0.025" |

125~150µm

5~6 Mil |

MCS172P20x50 |

172050 |

Sn60Pb40

Tin-Lead

100 µ-inch |

| 1.0mm |

Ø0.51mm

0.020" |

1.27mm

0.050" |

Ø86µm

0.0034" |

0.6268 N/mm

3.5792 lbs/Inch |

Ø0.635mm

0.025" |

125~150µm

5~6 Mil |

MCS172G20x50 |

192050 |

NiAu

Gold 10 µ-inch

Nickel 30~60µ-inch |

|

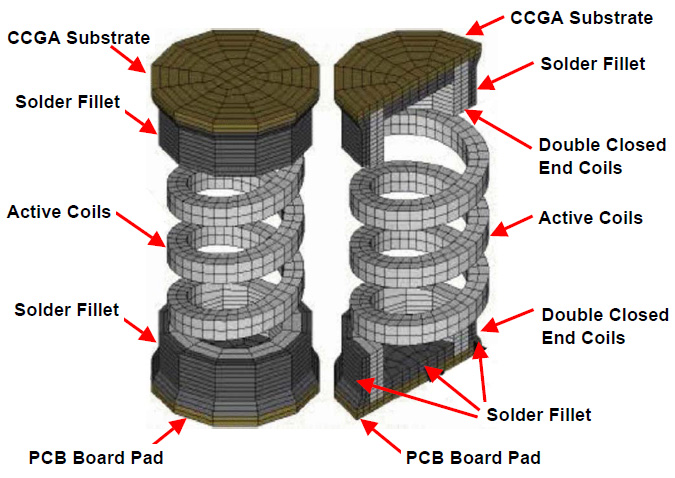

| Note 1: Stencil thickness may vary based on many factors such as solder paste powder size, flux and pad diameter. The fillet (after reflow) should cover the closed double end-coils without touching the active rings. Designers should use their own experience during process development. |

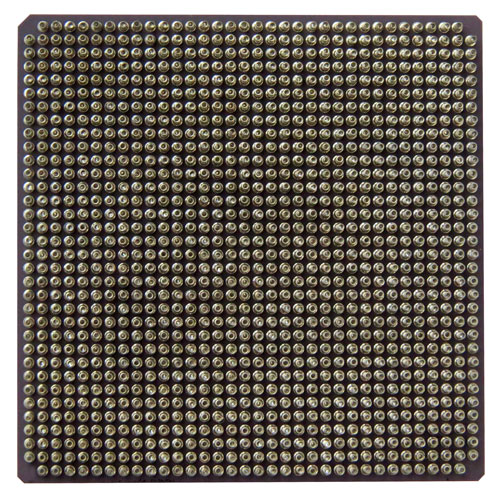

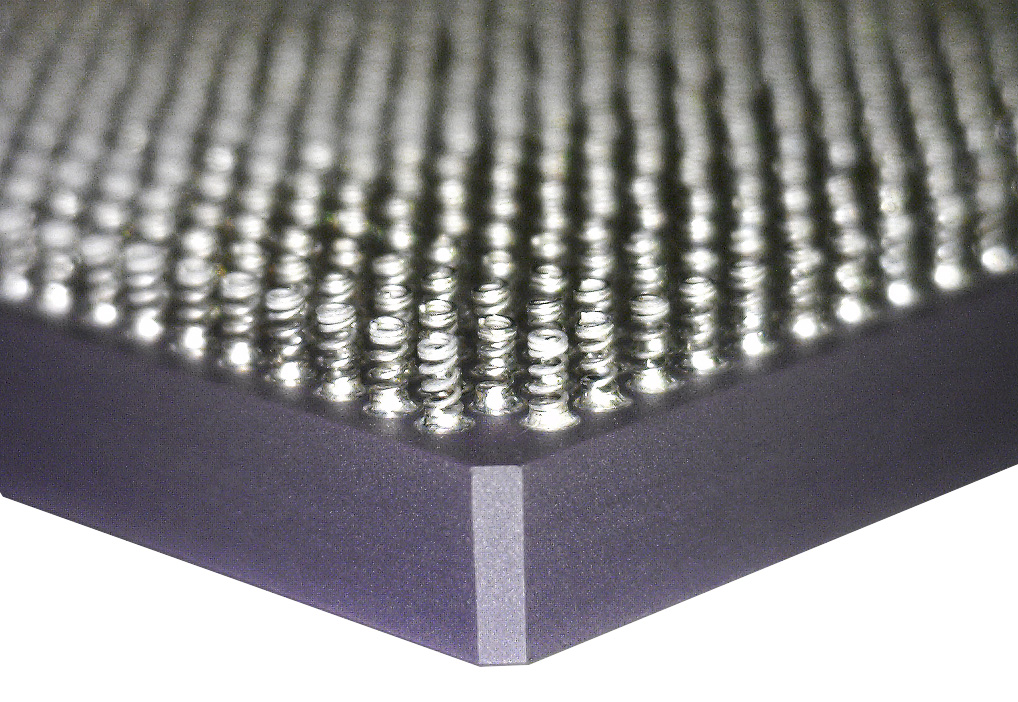

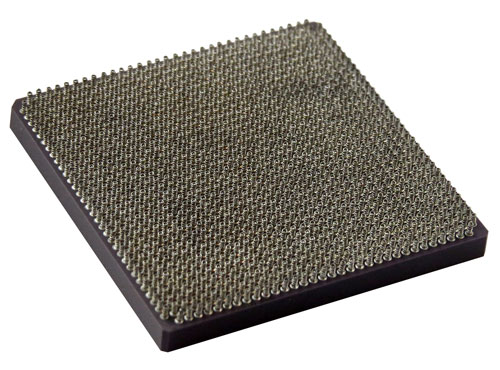

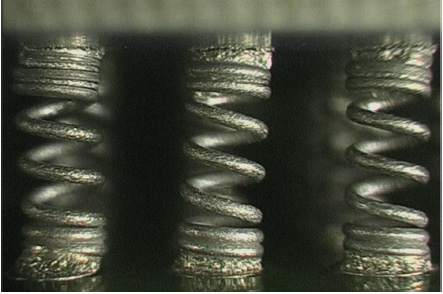

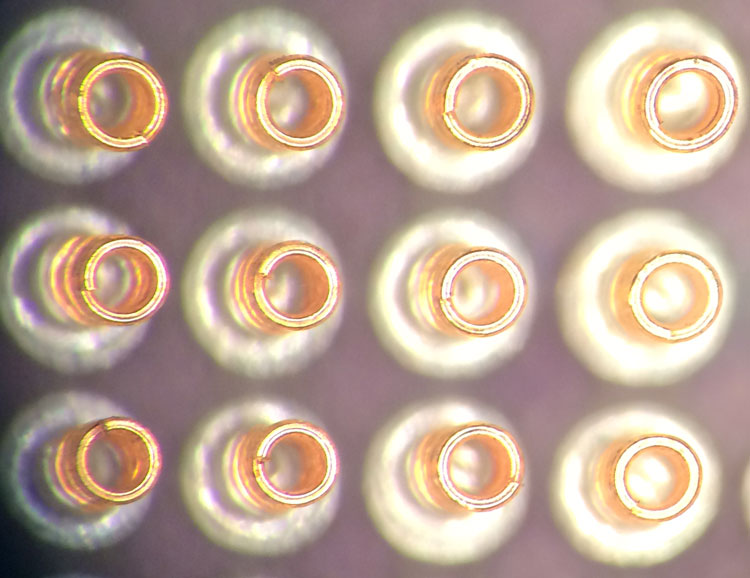

| Ø0.51mm x 1.27mm Micro-Coil Springs (Ø20 x 50mils) attached to CCGA1152 35x35mm Pitch 1.0mm |

|

|

|

|

| Bottom |

Detail |

Perspective |

Top |

| |

| |

| Description of Micro-coil Springs (MCS Series) |

| |

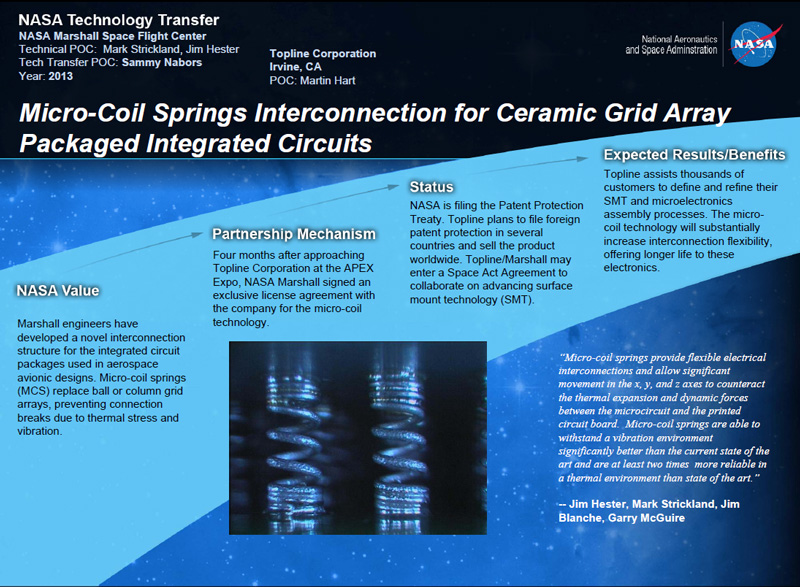

Micro-coil springs are a novel interconnect for CCGA (Ceramic Column Grid Array) IC packages for harsh environments. In tests using daisy chain test vehicles, Micro-coil springs absorbed extreme shock of up to 50,000g before failing. Commercial applications include aerospace, avionics, military, down-hole oilfield drilling and automotive electronics. |

|

2014 NASA Contest Winner Tech Briefs |

|

Daisy chain test vehicles described in

Micro-Coil Spring NASA document 2011. Characterization provided by Auburn University. Thermal performance described in 2009 Internship Report.

|

|

| Micro-coil springs are fabricated from beryllium copper C17200 (Alloy 25) per ASTM B 197. The coils are post-plated with electro-deposited Sn60/Pb40, 100 micro-inches minimum thickness.

Micro-coil springs may also be used in place of solder balls on plastic PBGA packages. After reflow at normal tin-lead temperature profiles, Sn63/Pb37 solder paste forms a fillet around the double coil ends of the spring. |

| |

Engineers at NASA's Marshall Space Flight Center developed this novel interconnection structure for integrated circuit packages. This innovation replaces traditional CCGA solder columns with the potential to extend life under harsh environments, extreme thermal stress, vibration and shock. The Micro-coil Spring technology provides flexibility in three dimensions between the ceramic (or plastic) package and the PCB board. This technology offers a distinct improvement over cast Pb90/Sn10 solder columns or copper-ribbon-wrapped Pb80/Sn20 solder columns, which have limited flexibility under shear stress. NASA's technology offers a novel alternative, providing better flexibility in high temperature and harsh environments. |

| |

| |

| Benefits: |

Improved Reliability:

- Reduced electrical failures due to connection breaks caused by thermal stress.

- >10,000 thermal cycles without failures.

Robust, Rugged and Tough:

- Resilient spring interconnect returns to home position.

- High tolerance for temperature extremes, thermal cycling and vibration.

- Improved three-dimensional flexibility versus traditional solder columns.

- Absorbs CTE (Coefficient of Thermal Expansion) mismatch between ceramic substrates and FR4/Polyimide PC boards.

Smaller Geometries:

- Standard I/O pitch 1.0mm to 1.27mm

- Reduced I/O pitch 0.5mm, 0.65mm and 0.8mm under development

Cost-Down:

- More reliable performance means fewer failures.

- Increased mean-time between failures.

Export:

- EAR99 classification.

- Not listed with a specific Export Control Classification Number (ECCN) on the Commerce Control List (CCL).

|

| |

|

| |

| |

Life Test Micro-Coil Compared to BGA

Weibull Analysis |

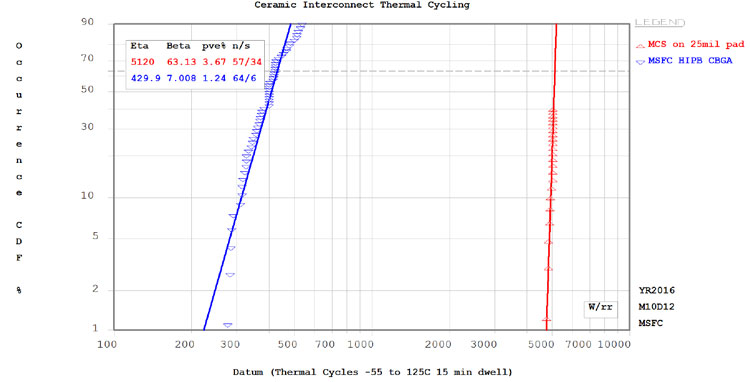

| Fig. 1A |

|

Fig. 1B |

|

|

|

Weibull#1

Ceramic CBGA compared to Micro-Coil Spring

CBGA Pb90/Sn10 ball experienced onset of failure after 300 cycles with last channels failing after 600 thermal-cycles -55°C to +125°C. Micro-Coil Springs mounted onto ceramic substrates of similar size survived on average 5000 thermal-cycles. |

|

Weibull#2

Plastic PBGA compared to Micro-Coil Spring

Plastic (Organic) PBGA Sn63/Pb37 ball experienced onset of failure after 2000 cycles with last channels failing after 4000 thermal-cycles -55°C to +125°C. Micro-Coil Springs mounted onto plastic substrates of similar size survived on average 20000 thermal-cycles. |

| |

| |

Micro-Coil Spring Models

Shock Simulation |

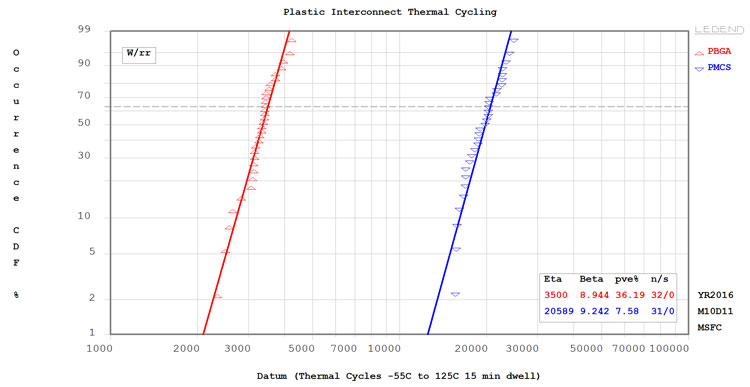

| Fig. 2 |

|

Fig. 3 |

|

|

|

MCS FEM (FINITE ELEMENT ANALYSIS)

MCS deflection time history after shock,

40,000g simulation with deflection milli-second time history.

Other g-levels are similar in contour with different magnitudes. |

|

Cut Away View

Double End Coil

|

| |

| |

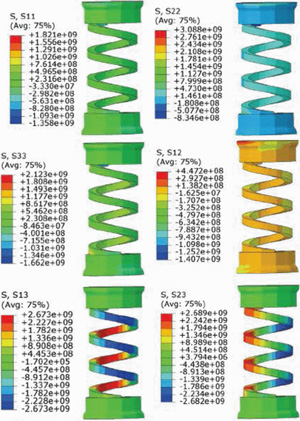

Micro-Coil Spring Models

Stress Contours During Compression and Maximum Deflection |

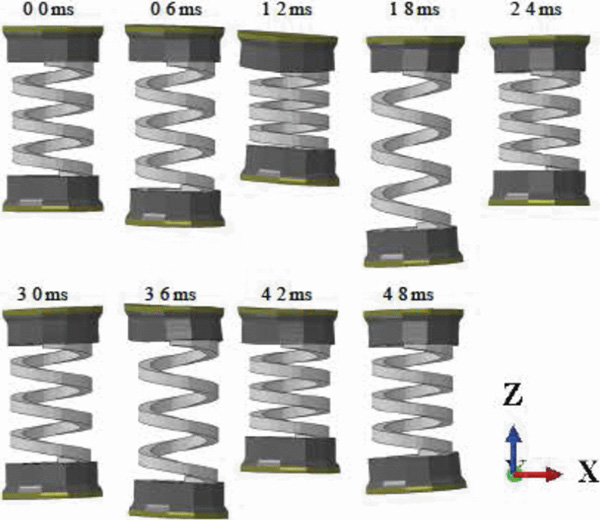

| Fig. 4 |

|

Fig. 5 |

|

|

|

While Compressed

Stress Contours

Stress concentrations occur only during the end of the compression cycle. Failure is likely to occur in the coil windings rather than at the solder fillet. |

|

Maximum Deflection

Stress Contours

Shear stresses in the coil are the highest in magnitude. Stress concentrations occur only for the two shear stress contours. Failure is likely to occur in the coil windings rather than at the solder fillet. |

| |

| |

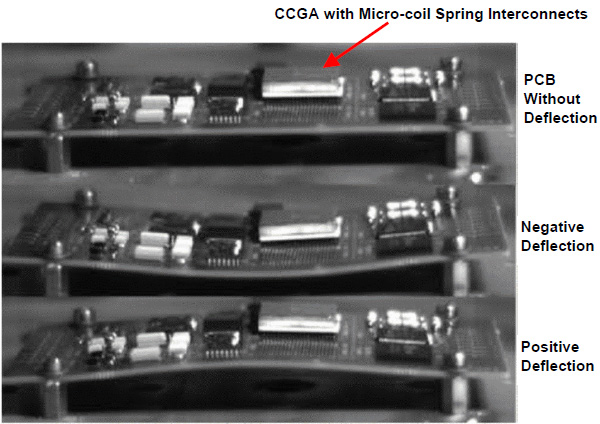

| PC Board Deflection and Failure Mode |

| Fig. 6 |

|

Fig. 7 |

|

|

|

1500g Drop Test

Un-deflected, Negative & Positive Deflection

Deflection during standard 1500g test

in accordance with JEDEC standards |

|

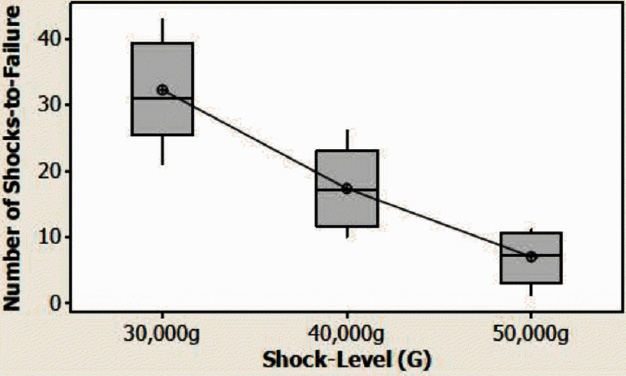

Comparison of Extreme Shock Repetition

Micro-Coil Springs 30,000g to 50,000g

to induce Failure Mode |

| |

| |

Comparison Failure Mode

After Application of Extreme Shock

Micro-coil Springs (MCS172P20x50) versus Pb90/Sn10 Wire Columns |

| Shock Level |

Micro Coil Spring |

Pb90/Sn10 Wire |

| 30,000g |

30-times before failure |

7-Times before failure |

| 40,000g |

16-times before failure |

5-Times before failure |

| 50,000g |

8-times before failure |

4-Times before failure |

| |

| |

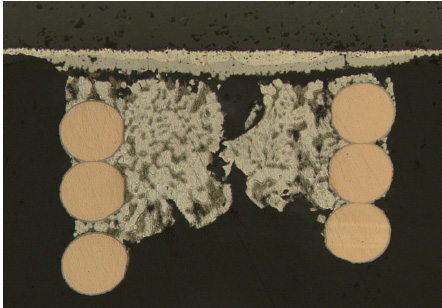

| View of Failure Mode |

| Fig. 8 |

|

Fig. 9 |

|

|

|

Cross Section View

Failed Micro-coil spring with a crack shown perpendicular to ceramic substrate (above double-end of the coil at top) after thermal cycling. |

|

Side View MCS172P20x50

Failure Micro-coil springs break in wire after thermal cycling. |

| |

| |

| |

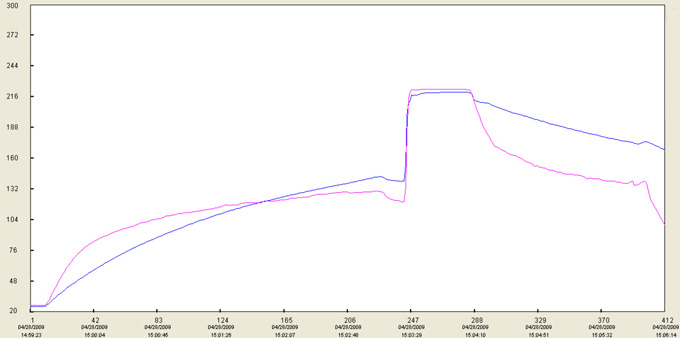

Fig. 10

Reflow Temperature Profile

|

|

Fig. 11

NASA Technology Transfer |

|

|

|

Vapor Phase Reflow.

Temperature profile used by NASA

to attach Micro-coil springs to ceramic CCGA

using Sn63/Pb37 solder paste. |

|

NASA Announces Technology Transfer

|

| |

| |

| |

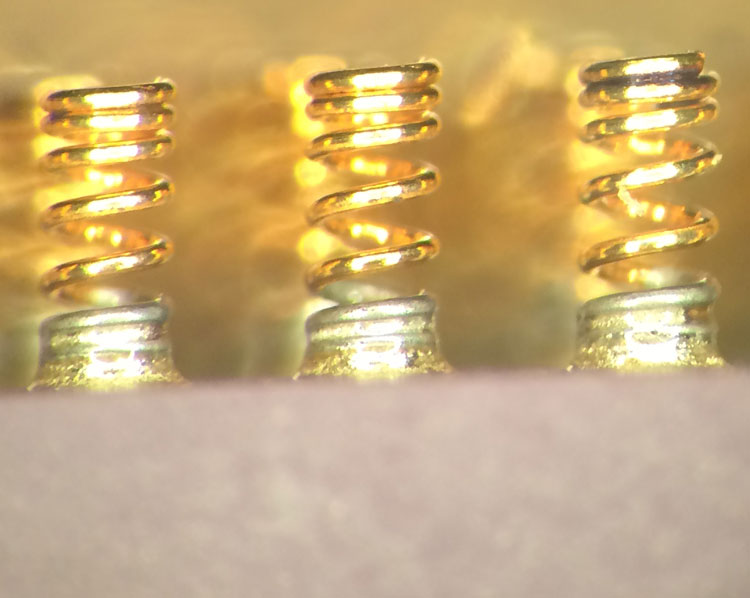

Fig. 12

Gold Plated Micro-Coil Spring

Side View

|

|

Fig. 13

Gold Plated Micro-Coil Spring

Top View |

|

|

|

RoHS Version.

Attached to ceramic substrate with SAC305 solder paste.

Stencil 6mil (150um) thick with Ø26mil (660um) aperture. |

|

0.5mm x 1.27mm coils.

Centered on Ø 0.8mm Ni-Au pad. |

| |

| |

|

|

Assembly Guidelines

PCB Pads and Solder Paste Stencil |

| I/O Pitch |

Spring

Diameter |

Spring

Length |

Recommended

Solder Mask

Type |

Pad

Diameter

Minimum |

Pad

Diameter

Maximum |

Paste

Stencil

Aperture |

Paste

Stencil

Thickness |

Coil Part Number |

| 1.0 to 1.27mm |

Ø 0.020"

0.508mm |

0.050"

1.27mm |

NSMD |

Ø 0.025"

0.635mm |

Ø 0.034"

0.86mm |

1:1 Size

of Pad |

5~6 mils

0.125~0.150mm |

MCS172P20x50 |

|

| Note 1. Solder Mask Type Definition: Non-solder Mask Defined (NSMD) pad recommended. Solder Mask Defined (SMD) Pad permissible under alternate conditions. |

| Note 2. Recommended to use vapor pahase reflow oven. |

| Note 3. Flux is allowed on CCGA Substrate |

| Note 4. Kester EP256 Sn63/Pb37 solder paste with Type 3 powder mesh and ROL0 no-clean flux used in trial runs. Other solder paste is permitted. |

Note 5. Kester EM907 SAC305 - Sn96.5/Ag3.0/Cu0.5 lead free solder paste with Type 3 powder mesh and ROL0 no-clean flux used in trial runs.

Other solder paste is permitted. |

| Note 6. Shearing (shaving) or trimming of Micro-coil springs is not required after attachment to the CCGA substrate, as is typically required for traditional solder colummns. |

| |

| |

|

|

Electrical Parameters

(Preliminary) |

Spring

Diameter |

Spring

Length |

Inductance

(500 MHz~10 GHZ) |

Capacitance |

DC

Resistance |

Coil Part Number |

Ø 0.020"

0.508mm |

0.050"

1.27mm |

≈ 4.7 nH |

To be

determined |

≈ 0.03 Ω |

MCS172P20x50 |

|

| |

| |

|

|

Micro-Coil Spring Part Number System

|

| MCS |

172 |

P |

20 |

X |

50 |

− |

Option |

| Column Type |

Alloy |

Plating |

Ø Diameter

Mils |

Packaging |

Length

Mils |

|

Option |

|

MCS = Micro Coil Spring |

172

BeCu

C17200

Alloy 25 |

P = Sn60/Pb40

G = Ni/Au

|

O.D. Diameter

06 = Ø0.15mm

08 = Ø0.20mm

10 = Ø0.25mm

12 = Ø0.30mm

14 = Ø0.35mm

16 = Ø0.40mm

18 = Ø0.45mm

20 = Ø0.50mm

35 = Ø0.89mm

|

X = Bulk |

Free Load Length

15 = 0.38mm

20 = 0.50mm

25 = 0.65mm

30 = 0.76mm

33 = 0.85mm

35 = 0.90mm

40 = 1.00mm

45 = 1.15mm

50 = 1.27mm

87 = 2.20mm

|

|

TBA |

|

| |

|

|

Micro-Coil Spring Drawing Number

|

| 17 |

20 |

50 |

| MCS Plating |

Ø Diameter

Mils |

Length

Mils |

MCS Micro Coil Spring

17 = Sn60/Pb40

19 = Ni/Au

Ni 30~60 micro-inches (0.76~1.5µm)

Au 10 micro-inches (0.25µm) |

O.D. Diameter • Typical Pitch

06 = Ø0.15mm

• P~0.4mm

08 = Ø0.20mm

• P~0.5mm

10 = Ø0.25mm

• P~0.65mm

12 = Ø0.30mm

• P~0.8mm

14 = Ø0.35mm

• P~0.8mm

16 = Ø0.40mm

• P~1.0mm

18 = Ø0.45mm

• P~1.0mm

20 = Ø0.50mm

• P~1.0mm

35 = Ø0.89mm

• P>1.5mm

|

Micro Coil Spring

15 = 0.38mm

20 = 0.50mm

25 = 0.65mm

30 = 0.76mm

35 = 0.90mm

40 = 1.00mm

45 = 1.15mm

50 = 1.27mm

87 = 2.20mm

|

|

| |

|

|

Properties of Performance

|

| Alloy |

Solidus |

Liquidus |

Density

gm/cc |

Modulus of

Elasticity |

Electrical

Conductivity

% of IACS |

Thermal

Conductivity |

CTE

Coefficient

Thermal

Expansion |

Tensile

Stength |

Beryllium Copper

Hard Temper TD05

C17200

Alloy 25

Cu 98%

Be 1.8%

Co+Ni 0.2% |

-- |

865°C |

8.36 |

131 GPa |

22~28 |

105 W/m-K |

17.5ppm/°C |

1100 MPa |

| |

Pb90/Sn10

Solder |

275°C |

302°C |

10.5 |

490 GPa |

8.2 |

36 W/m-K |

27.9ppm /°C |

30 MPa |

| |

Pb80/Sn20

Solder |

183°C |

280°C |

10.0 |

~500 GPa |

8.7 |

37 W/m-K |

26.5ppm /°C |

33 MPa |

|

Ambient temperature is ~25 °C.

Coefficient of thermal expansion is defined as the fractional increase in the length per unit rise in temperature.

CTE units may be expressed in units of: µm/m/°C or ppm/°C or µ-inch/in/°C.

Metric Units of GPa are gigapascals (109Pa) • Metric Units of MPa are megapascals (106Pa)

Data is for information only and is not guaranteed for accuracy. |

| |

| |

| |

| ECCN: EAR99 Export Administration Regulations (EAR) |

| HS Code: 8542.90.0000 ELECTRONIC INTEGRATED CIRCUITS AND MICROASSEMBLY PARTS |

| ITAR: Micro-coil springs and dummy daisy chain CCGA are not

restricted. |

| |

| |

Download Solidworks® e-Drawing viewer to enjoy 360° rotatable models. Download Solidworks® e-Drawing viewer to enjoy 360° rotatable models.

For PC •

MAC Version

| |

|

TopLine Corporation

95 Highway 22 W

Milledgeville, GA 31061, USA

Toll Free USA/Canada (800) 776-9888

International: 1-478-451-5000

Email: sales@topline.tv

©2022 TopLine. All Rights Reserved.

Home

|

|

|

|

|