| |

| CN & CF Series

Al-SiC Heat Spreaders |

|

| |

|

Catalog •

Columns •

Sockets •

Library •

Mat'l Properties •

Micro-Coil Spring •

PCB •

Trays •

Tools •

Flip-Pack®

|

| |

| ABOUT Heat Spreaders:

Heat spreaders are made from Aluminum mixed with Silicon-Carbide particles (AlSiC). This combination results in a low CTE composite that is able to dissipate heat generated by the die on ceramic CCGA packages. AlSiC have high thermal conductivity and low thermal expansion compatible with semiconductor silcon chips and ceramic substrates enabling higher performance to prevent fatigue failure. The AlSiC heat spreader is attached directly to the top of the power chip using a thermal interface material (TIM) such as SE 4450 Adhesive. The thermal conductivity rate of AlSiC permits chip heat to be distributed evenly with higher performance for reliability and stability. AlSiC-8 material composition is 37% volume of Al and 63% volume of SiC. The heat sink is plated with electroless nickel (Ni) 4~8 um (157~315 micro-inch) thickness.

|

| |

| |

| |

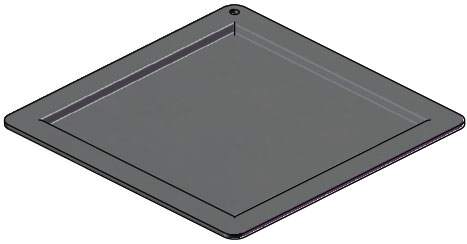

| H-CAP "HAT" Dome Shaped Heat Spreader for BGA |

|

|

| TOP |

BOTTOM |

| DWG |

BGA Size (mm) |

Total

Height |

Die

Height |

Part Number |

Style |

Material |

SolidWorks

Model |

| 213710 |

13 x 13mm |

1.38mm |

0.88mm |

H-CAP13A |

Hat Dome Lid |

Cu Alloy |

Model |

| 217710 |

17 x 17mm |

1.3mm |

0.8mm |

H-CAP17B |

Hat Dome Lid |

Cu Alloy |

Model |

| 219710 |

19 x 19mm |

1.3mm |

0.8mm |

H-CAP19A |

Hat Dome Lid |

Cu Alloy |

Model |

| 221710 |

21 x 21mm |

1.3mm |

0.8mm |

H-CAP21A |

Hat Dome Lid |

Cu Alloy |

Model |

| 223710 |

23 x 23mm |

1.3mm |

0.8mm |

H-CAP23A |

Hat Dome Lid |

Cu Alloy |

Model |

| 225710 |

25 x 25mm |

1.3mm |

0.8mm |

H-CAP25A |

Hat Dome Lid |

Cu Alloy |

Model |

| 227710 |

27 x 27mm |

1.3mm |

0.8mm |

H-CAP27A |

Hat Dome Lid |

Cu Alloy |

Model |

| 229710 |

29 x 29mm |

1.3mm |

0.8mm |

H-CAP29A |

Hat Dome Lid |

Cu Alloy |

Model |

| 231710 |

31 x 31mm |

1.3mm |

0.8mm |

H-CAP31A |

Hat Dome Lid |

Cu Alloy |

Model |

| 235710 |

35 x 35mm |

1.3mm |

0.8mm |

H-CAP35B |

Hat Dome Lid |

Cu Alloy |

Model |

| 237710 |

37.5 x 37.5mm |

1.3mm |

0.8mm |

H-CAP37.5A |

Hat Dome Lid |

Cu Alloy |

Model |

| 240710 |

40 x 40mm |

1.3mm |

0.8mm |

H-CAP40A |

Hat Dome Lid |

Cu Alloy |

Model |

| 242710 |

42.5 x 42.5mm |

1.3mm |

0.8mm |

H-CAP42.5A |

Hat Dome Lid |

Cu Alloy |

Model |

| 247710 |

47.5 x 47.5mm |

1.85mm |

0.85mm |

H-CAP47.3A |

Hat Dome Lid |

Cu Alloy |

Model |

| 250710 |

50 x 50mm |

1.8mm |

0.8mm |

H-CAP50A |

Hat Dome Lid |

Cu Alloy |

Model |

| 252710 |

52.5 x 52.5mm |

1.8mm |

0.8mm |

H-CAP52.5A |

Hat Dome Lid |

Cu Alloy |

Model |

| 255710 |

55 x 55mm |

1.8mm |

0.8mm |

H-CAP55B |

Hat Dome Lid |

Cu Alloy |

Model |

| 260710 |

60 x 60mm |

1.8mm |

0.8mm |

H-CAP60A |

Hat Dome Lid |

Cu Alloy |

Model |

|

| Base Material: Cu Copper Alloy UNS C10200 or C11000. Half-Hard. Oxygen Free |

| Plating: Nickel (Ni) 5um Min. Semi-Finish |

| Vent Hole: For vented BGA |

| |

| |

| |

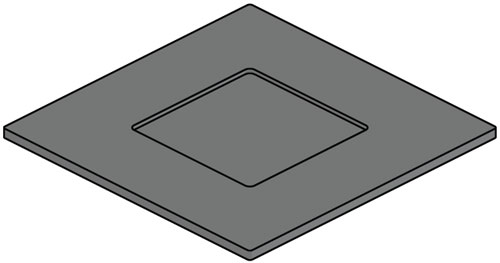

| F-CAP FLAT Cavity Heat Spreader for BGA |

|

|

| TOP |

BOTTOM |

| DWG |

BGA Size (mm) |

Total

Height |

Die

Height |

Part Number |

Style |

Material |

SolidWorks

Model |

| 210790 |

10 x 10mm |

1.6mm |

0.8mm |

F-CAP10A |

Flat Cavity Lid |

Cu Alloy |

Model |

| 242790 |

42.5 x 42.5mm |

1.6mm |

0.8mm |

F-CAP42.5A |

Flat Cavity Lid |

Cu Alloy |

Model |

| 252790 |

52.5 x 52.5mm |

1.6mm |

0.8mm |

F-CAP52.5A |

Flat Cavity Lid |

Cu Alloy |

Model |

|

| Base Material: Cu Copper Alloy UNS C10200 or C11000. Half-Hard. Oxygen Free |

| Plating: Nickel (Ni) 5um Min. Semi-Finish |

| Custom sizes available. |

| |

| |

| |

| MATERIAL SPECIFICATIONS |

| Material |

Density

g/cm3 |

CTE

ppm/oC

[25~150°C] |

Youngs

Modulus

GPa |

Thermal

Conductivity

W/mK @25°C |

Fracture

Toughness

MPa*m1/2 |

Mohs Scale

of Hardness |

Bending

Strength |

AlSiC-8

37% Vol Al

63% Vol SiC |

2.83 |

8~9 |

188 |

170~189 |

8 |

8~9 |

3200 |

UNS C10200

Copper Alloy |

8.9 |

17 |

115 |

400 |

- |

- |

- |

| |

| |

| |

Recommended Thermally Conductive

SE 4450 Adhesive

for Attaching Heat Spreaders to Ceramic Substrates |

| |

|

Download Solidworks® e-Drawing viewer to enjoy 360° rotatable models. Download Solidworks® e-Drawing viewer to enjoy 360° rotatable models.

Download

| |

|

TopLine Corporation

95 Highway 22 W

Milledgeville, GA 31061, USA

Toll Free USA/Canada (800) 776-9888

International: 1-478-451-5000

Email: sales@topline.tv

©2022 TopLine. All Rights Reserved.

Home

|

|

|